name gyratory crusher of

2023-12-20T00:12:12+00:00

2 GYRATORY CRUSHERS

Sectional view of longshdt suapendcd gyratory cmha (courtcly of AlluCholmen) When the feed to a gyratory crusher is runofmine it is normally referred to as a primary crusher Similar crushers that are used follow ing these units are known as secondaries Gyratory crusher an overview sciencedirect topics,jaw and gyratory crushers are used for initial size reduction to convert big rocks into small stones this is generally followed by a cone crusher combination of rod mill and ball mills are then used if the ore must be ground below 325 mesh instead of grinding the ore dry, slurry is used as feed for rod or ball mills, to avoid dustingname of gyratory crusher iron ore mining groundsThe primary gyratory crusher wear parts have the most important role in rock size reduction in mine operations as the crushing process starts from a primary crusher The highest possible wear life is combined with mechanical reliability through the component life cycleGyratory Crusher Parts For Popular Brands, Gyratory Crusher(vertical compound crusher) is a mining and other industrial sectors crushing all kinds of hard materials typical of crushing equipment also known as compound crusher is stone production line and sand production line commonly used crusher deviceGyratory Crusher,Gyratory Crushers,vertical compound Gyratory crusher an overview sciencedirect topics,jaw and gyratory crushers are used for initial size reduction to convert big rocks into small stones this is generally followed by a cone crusher combination of rod mill and ball mills are then used if the ore must be ground below 325 mesh instead of grinding the ore dry, slurry is used as feed for rod or ball mills, to avoid dustingname of gyratory crusher iron ore mining grounds

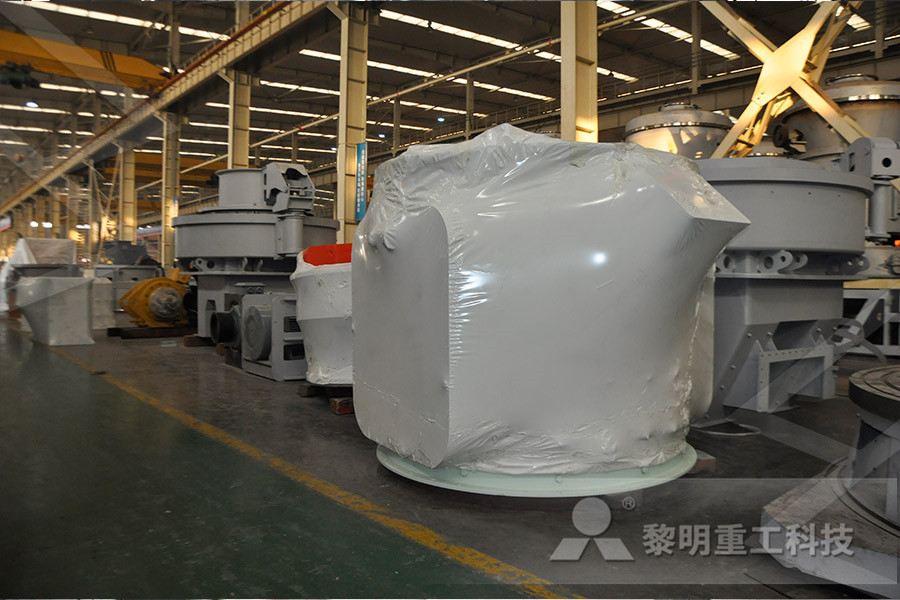

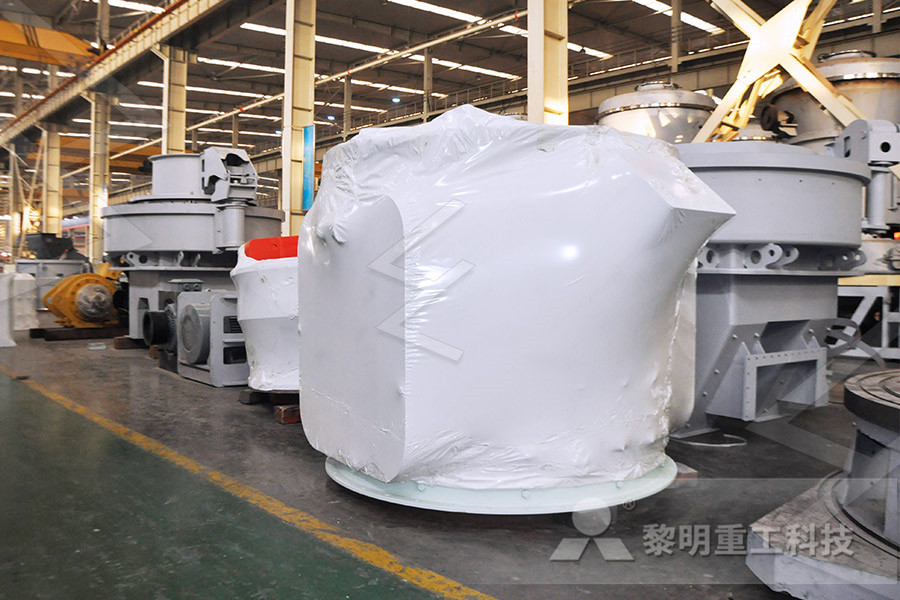

Gyratory Crusher,Gyratory Crushers,vertical compound

Gyratory Crusher (vertical compound crusher) Has broken than large, advanced design, reliable performance, smooth, high production capacity, high production capacity, uniform particle size and other characteristics are widely used in metallurgy, building materials, chemicals and utilities sectors and other industriesPrimary Gyratory Crusher High Performance GY Series A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening Gyratory Gyratory Crusher Hazemag North America60110 Gyratory Crusher / Crusher Parts For Stone Crushing Mining Product Name: Gyratory Crusher Applications: Widely used in mining industry, Quarrying Aggregate, metallurgical industry, construction industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone, quartz and so on60110 Gyratory Crusher / Crusher Parts for Stone Standard gyratory crushers require personnel to get beneath the crusher, a confined and hazardous workspace where they are at considerable risk We remain the only vendor to offer a fully Top Service crusher and the TSUV takes this commitment to safety a step further with the creation of Safer, smarter, more powerful crushing T 3 0 1990 Cu Concentrator throughput (kTPD) % Copper 1995 2000 2005 2010 2015 2020 2025 0 02 04 06 08 1 12 14 16 18 40 80 120 160 200 240 280 320 360 More power without a significant increase in crusher footprint Greater capacity without compromising on performance Optimised speed to balance throughput and wear rates Enlarged feed opening for greater flexibilityTop service TSUV Gyratory Crushers Safer, smarter and

Gyratory crusher model and impact parameters

The crusher parameters that affect energy consumption were also identified A case study of an operating dolomite mine was performed The results indicated that by changing the burden, spacing and crusher closedside setting, the overall (blasting and crushing) costs could be reduced by 47% to 79% annually Difference between jaw crusher and gyratory crusher Any of you that are at all familiar with the Gyratory crushers and Cone Crushers that the former are used as Primary crushers will probably note many similarities between the types Each use a coneGyratory Crusher Cone Crusher Mantle DifferencesGyratory Crusher Liners — find the right solution for your application Gyratory Crusher Liners solutions help enhance the efficiency of your operation and lower your operating expenses We offer many grades of Gyratory Crusher Liners, enabling you to find the ideal solutionGyratory Crusher Liners The process layout of gyratory crusher is to ensure that the equipment reaches the optimal working conditions and production conditions Like other coarse crushing equipment, they all need to meet the basic requirements, and at the same time, they must be reasonably designed according to the natural conditions of the site, equipment maintenance Tips for process layout of gyratory crusher SifetBabo Gyratory crusher an overview sciencedirect topics,jaw and gyratory crushers are used for initial size reduction to convert big rocks into small stones this is generally followed by a cone crusher combination of rod mill and ball mills are then used if the ore must be ground below 325 mesh instead of grinding the ore dry, slurry is used as feed for rod or ball mills, to avoid dustingname of gyratory crusher iron ore mining grounds

Gyratory Crusher l Introduce, Working Principle JXSC

Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher The gyratory crushing equipment has a bright future in the mineral processing market Its working part is a highspeed rotary crushing roller, which is coupled with a pair of curved crushing plates arranged symmetrically on the left and the right to Primary Gyratory Crusher High Performance GY Series A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening Gyratory Gyratory Crusher Hazemag North America Difference between jaw crusher and gyratory crusher Any of you that are at all familiar with the Gyratory crushers and Cone Crushers that the former are used as Primary crushers will probably note many similarities between the types Each use a coneGyratory Crusher Cone Crusher Mantle DifferencesThe crusher parameters that affect energy consumption were also identified A case study of an operating dolomite mine was performed The results indicated that by changing the burden, spacing and crusher closedside setting, the overall (blasting and crushing) costs could be reduced by 47% to 79% annuallyGyratory crusher model and impact parameters Standard gyratory crushers require personnel to get beneath the crusher, a confined and hazardous workspace where they are at considerable risk We remain the only vendor to offer a fully Top Service crusher and the TSUV takes this commitment to safety a step further with the creation of Safer, smarter, more powerful crushing

Gyratory Crusher Liners

Gyratory Crusher Liners — find the right solution for your application Gyratory Crusher Liners solutions help enhance the efficiency of your operation and lower your operating expenses We offer many grades of Gyratory Crusher Liners, enabling you to find the ideal solutionThe process layout of gyratory crusher is to ensure that the equipment reaches the optimal working conditions and production conditions Like other coarse crushing equipment, they all need to meet the basic requirements, and at the same time, they must be reasonably designed according to the natural conditions of the site, equipment maintenance Tips for process layout of gyratory crusher SifetBaboThe gyratory crusher reliability program maps the crusher mantle and concaves for trending, thickness to ensure integrity of the mainshaft Toll Free USA +1 (866) 4191619 Worldwide +1 (715) 2142162Gyratory Crusher Reliability Program Global Physical T 3 0 1990 Cu Concentrator throughput (kTPD) % Copper 1995 2000 2005 2010 2015 2020 2025 0 02 04 06 08 1 12 14 16 18 40 80 120 160 200 240 280 320 360 More power without a significant increase in crusher footprint Greater capacity without compromising on performance Optimised speed to balance throughput and wear rates Enlarged feed opening for greater flexibilityTop service TSUV Gyratory Crushers Safer, smarter and