attrition mill definition paint

2020-08-16T13:08:35+00:00

Attrition Mill Definition of Attrition Mill by Merriam

Definition of attrition mill : a machine in which materials (such as grain or spices) are pulverized between two toothed metal disks rotating in opposite directionsattrition mill [ ə′trishən ‚mil] (mechanical engineering) A machine in which materials are pulverized between two toothed metal disks rotating in opposite directions McGrawHill Dictionary of Scientific Technical Terms, 6E, Copyright © 2003 by The McGrawHill Attrition mill Article about attrition mill by The Free Mill that grinds abrasively, using rubbing action rather than impact shattering to disintegrate material Ref: Pryor, 3 ii A disintegrator depending chiefly on impact to reduce the particle size of the charge Attrition mills are sometimes used in the clay building materials industry to deal with the tailings from the edgerunner mill Ref: DoddDefinition of attrition mill The attrition mill is a device for mechanically reducing solid particle size by intense agitation of a slurry of material being milled and coarse milling media For example, in 10 hours of milling, specific surfaces of 40 and 25 m 2 /g were obtained for alumina and barite, corresponding to 38 and 56 nm equivalent spherical diameter, respectivelyAttrition mill operating characteristics ScienceDirectThe attrition mill is a device for mechanically reducing solid particle size by intense agitation of a slurry of material being milled and coarse milling mediaAttrition mill operating characteristics ScienceDirect

attritionmill definition and meaning

attritionmill: A mill, usually centrifugal, in which grain is pulverized by the mutual attrition of its particles, and by frictional contact with the sides Often materials which have been coarsely ground by other mills, are passed through an attrition mill for blending or smoothing out an ingredient or mixture containing liquids which may have clumps The discs of an attrition mill are generally in a vertical position so that materials not capable of reduction can pass by gravity out of the grinding areaAttrition Mills Mill (Grinding) Materials Science MIKRONS ® Attritor is used for producing fine homogenous dispersions quickly repeatedly under controlled conditions Used for the manufacture of ceramics , inks, paints,coatings, metal oxides, ferrites, chocolates, chemicals pharmaceuticals The Attritor is often referred to as a agitated ball millAttritor, How attritor Works, Attritor working, Dry What is the definition of paint mill? What is the meaning of paint mill? How do you use paint mill in a sentence? What are synonyms for paint mill?Paint Mill Definition of Paint Mill by Oxford Ultra fine grinding of talc in attrition mill (attritor) was carried out in various time intervals from 5 to 15 min paint, food and cosmetic As the basis of this model is the fluid High performance attrition in stirred mills

grinding mills attrition

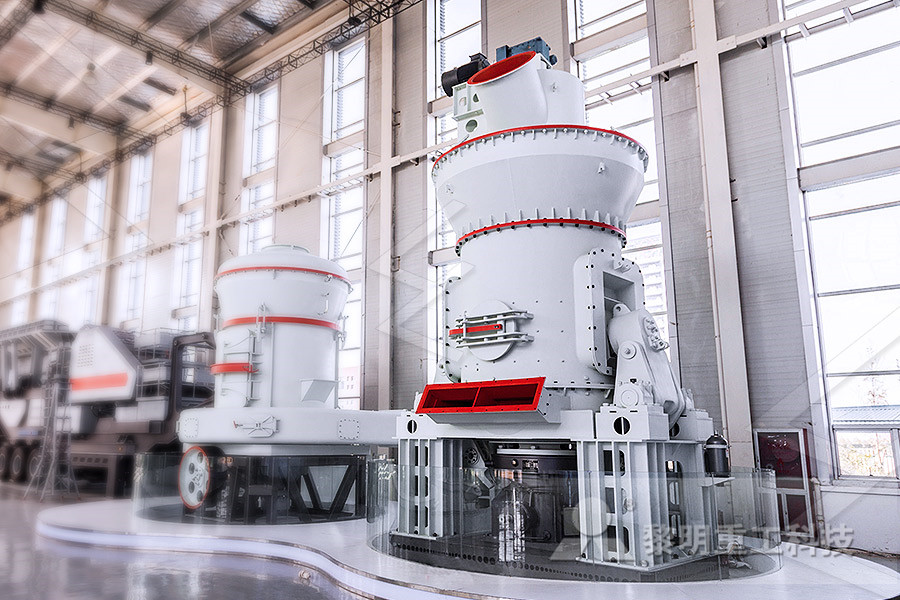

through the mill’s cooling jacket Adjusting the mill’s materialtomedia ratio and retention time also can limit heat generated during grinding How the attrition mill works The dry, finegrinding attrition mill consists of a stationary, cylindrical, vertical grinding chamber, as shown in Figure 1 A rotating vertical shaft Tips: How to applyAttrition mill oxide, also leady oxide, is more commonly produced in Europe and Asia The diagram reveals that for antimony concentrations lower than 35%, Coal Pulverizer, Coal Pulverizer Mill, Coal Mill attrition mill diagram chinaAttrition is applied to sandy material to remove particle surface contamination or undesired cuttings before flotation Working in stirred mills and applying special process conditions, attrition High performance attrition in stirred millsWet milling, also called wet media milling, is a process in which particles are dispersed in a liquid by shearing, by impact or crushing, or by attrition A mill is charged with media (small beads or spheres) and activated by a highspeed agitator shaft to separate the individual particlesWet Milling Process Custom Milling ConsultingDefinition Description Components Paint Formulation 45 Paint and Varnish Removers Paint Removal Solvent Paint and Varnish Removers Nochlorinated Solvent Paint Removers 46 Machinery Equipments for Paint Varnish Industry Triple Roil Mill Sand Grinder Colloid Mill Amalgamator or Horizontal Mixer Attrition Mill Roll Mill Cone Blender Mixer Modern Technology of Paints, Varnishes Lacquers (2nd

Ball Mills For Pigment Mixing MC World

Ball Mill Definition For Paint Industry Feb Ball Mill Definition For Paint Industry Ball mill wikipedia a ball mill is a type of grinder used to grind blend and sometimes for mixing of materials for use in mineral dressing processes paints pyrotechnics ceramics and selective laser sintering it works on the principle of impact and attrition The mill also includes the processes of attrition and impact, although these actions are limited if the material is easily reduced by cutting and the screen limiting discharge has large perforations The mill consists of a rotating shaft with four attached parallel knives and a screen occupying one fourth of the 360 degree rotation The mill is Chapter 18 Feed Milling Processes FAODefinition of Composite Materials The word ‗composite‘ in composite materials means that two or mor e materials are attrition ball mill Courtesy of Union Proce ss, Akron, OH (PDF) Manufacturing process ResearchGate Attritor Mill An attritor is a ball mill system in which the balls, together with the material to be milled are set in motion by a shaft with stirring arms, rotating 1002000rpm Cylindrical vessel is usualy water cooled because of the considerable heat generated by the process Dry,wet (water, inorganic liquids) milling is possible inert gasMME 3518 POWDER METALLURGY ROD MILL CAPACITIES The above tables list some of the most common Open End Rod Mill sizes Capacities are based on medium hard ore with mill operating in closed circuit under wet grinding conditions at speeds indicated For dry grinding, speeds and power are reduced and capacities drop 30 to 50% ROD MILL General ArrangementDimensionsRod Mills Mineral Processing Metallurgy

grinding mills attrition

through the mill’s cooling jacket Adjusting the mill’s materialtomedia ratio and retention time also can limit heat generated during grinding How the attrition mill works The dry, finegrinding attrition mill consists of a stationary, cylindrical, vertical grinding chamber, as shown in Figure 1 A rotating vertical shaft Tips: How to apply The mill also includes the processes of attrition and impact, although these actions are limited if the material is easily reduced by cutting and the screen limiting discharge has large perforations The mill consists of a rotating shaft with four attached parallel knives and a screen occupying one fourth of the 360 degree rotation The mill is Chapter 18 Feed Milling Processes FAO Autogenous attrition grinding has been applied to a North Carolina dunite to produce an olivine foundry sand Recently there has been increasing interest in the grinding of calcium carbonate minerals because of their expanded use as paint pigments, extenders, and fillers, and also in plasterboard joint cementAutogenous Attrition Microgrinding 911 MetallurgistBall Mill Design/Power Calculation 2018/04/08The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and maximum and mechanism of ball mill used in paintAcademiaedu is a platform for academics to share research papers(PDF) Chemistry Pigments For Paints Giovanni

Glossary of Steel Industry Terms American Iron and

These include the slabbing mill, hot roll mills, cold roll mills, SR mills, and DR mills Any operating unit that reduces gauge by application of loads through revolving cylindrical rolls; operation can be hot or cold The elevated temperature rolling mill is the Hot Mill and is capable of reducing the gauge of a slab 9299% Roughing Stand 1 Figure 101 shows the difference in energy efficiency between a laboratory ball mill and a stirred mill grinding a gold ore using 6 mm diameter alumina balls as media At a fine grind size there is a clear advantage in energy consumption for a stirred mill over the tumbling mill However, as the grind size coarsens, the difference in specific energy required to achieve the grind lessensStirred Mills – Ultrafine Grinding ScienceDirect Note that the definition of particle size in Bonds law is different: D80= Particle size such that 80% by weight of the sample is smaller than it Bonds law is often written in terms of the work index (Wi) as, Where the work index is defined as the energy required per unit mass in kWh/ton to reduce an infinitely large particles to D80 = 100 μmFM 306: SIZE REDUCTION AND SIEVING growth With the start up of a steel mill in Davao (see related news), and plans for future expansions (see related news), this is a good sector to watch The medium tech group provides raw materials to the other sectors, enabling much needed integration across the value chain These group provides fuel, cement, iron and steel, plastics and rubberTHE PHILIPPINE MANUFACTURING INDUSTRY PROFILE Definition, objectives of size reduction and size separation, factors affecting size reduction, laws governing energy and power requirements of mills including ball mill, hammer mill, fluid energy mill etc, sieve analysis, standards of sieves, size separation equipment shaking and vibrating screens, gyratory screens, cyclone separator, air separator, bag filters, cottrell precipitator SIZE REDUCTION AND SIZE SEPARATION Blogger