primary crusher design

2023-09-03T11:09:41+00:00

Primary Crusher Selection Design 911 Metallurgist

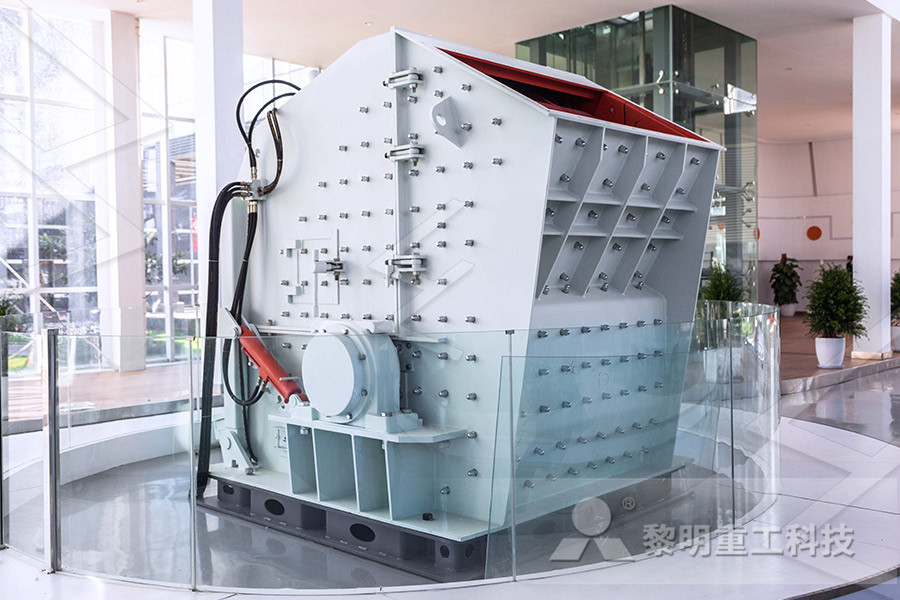

Dependability and long service life are landmarks of good primary crusher design of up to 30 yrs The selection of the primary crusher must consider bestinbreed maintenance services as the whole mine’s production goes through 1 or 2 of these 21 The primary crusher The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour) The driving flywheel has a diameter of 25 meters and is motor driven through six vbeltsPrimary Crusher an overview ScienceDirect TopicsPrimary Impact Crusher Primary impact crusher is 's new product absorbing international latest technology As the crusher's heart, rotor is the most important part PFP impact crushers are generally used as a primary crushers for crushing quarry rock, which are designed for crushing low abrasive and medium hard materialsprimary crusher and secondary crusher design The term “primary crusher,” by definition, might embrace any type and size of crushing machine The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only Primary Crushing 911 MetallurgistPrimary coal crusher design occl primary crusher design at thermal power plant primary crushers used in power plant solution for mining quarry crusher machine in power plants primary crusher design at thermal power plant is manufactured from shanghai,it coal crusher is the main crushing machine used in coal crushing plantPrimary Coal Crusher Design moribito

primary crusher plant design pictures

Primary Crusher Selection Design In inpit crushing, the primary function of a crusher is to provide a smaller uniform product size for each of transport by the conveying system Minimum power consumption in part of a good design For their coarse duty, primary crushers use, comparatively lower energy, to other systemsget priceGenerally primary jaw crushers have the square opening design, and secondary jaw crushers have rectangular opening design Jaw crushers are used as primary crushers in a mine or ore processing plant or the first step in the process of reducing rock get pricePrimary Crusher Design Pdf SoftwareTAKRAF’s range of primary crushing plants Primary crushing plants can be equipped with gyratory crushers, jaw crushers, twinshaft sizers, doubleroll crushers, impact crushers or hammer crushers, depending on material properties and required throughputsPrimary Crushing Plants TAKRAF GmbHPrimary crusher T he raw material from mines is processed first in primary cru shers The input of these crushers is relatively wider The main objective is to design impact stone crusher (PDF) Design of Impact stone crusher machine Gyratory crusher is generally used as a primary crusher The crusher is popular due to its high throughput capacity and the large sized opening The crusher is well suited for handling direct feed from haul/dump trucks The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strengthConstruction, Working and Maintenance of Crushers for

design parameters of primary crusher salzgrotte

crusher design parameters determined Primary Crusher Selection Design How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given byCivil, structural, and mechanical design for the addition of a primary crusher in the quarry at the Get Price Brick How Products Are Made The term brick refers to small units of building material, often made from fired ideal material for structures in confined spaces, as well as for curved designs To produce brick, the raw design of primary crusher building pochirajucoopening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square Generally primary jaw crushers have the square opening design, and secondary jaw crushers have rectangular opening design Jaw crushers are used as primary crushers in a mine or ore processing plant or the first step in the process of reducing rockget pricePrimary Crusher Design Pdf SoftwarePrimary Crusher Selection Design In inpit crushing, the primary function of a crusher is to provide a smaller uniform product size for each of transport by the conveying system Minimum power consumption in part of a good design For their coarse duty, primary crushers use, comparatively lower energy, to other systemsget priceprimary crusher plant design picturesPrimary crushing of lumps The robust KVB series primary lump crushers are suited to the coarse grinding of agglomerates and lumps which are hard and brittle Should the product still be too coarse after the primary crusher, we recommend using our MKB lump crusher to grind the coarse goods to Primary lump crusher KVB Paul Groth Mühlenbau

Design of a crushing system that improves the crushing

has to follow these three steps: crusher selection, crusher layout and process design 24 Crushers A crusher is a tool or machine that is used to reduce the size of a large solid particle to a smaller solid particle The ore can have a size of up to 400mm There are many types of crushers but the major ones are the jaw, gyratory and the cone Primary crushing plants are the first step in material processing and/or link between mining truck and belt conveyor, train or road TAKRAF’s range of primary crushing plants Primary crushing plants can be equipped with gyratory crushers, jaw crushers, twinshaft sizers, doubleroll crushers, impact crushers or hammer crushers, depending on Primary Crushing Plants TAKRAF GmbH The crusher was born out of a need for a high capacity underground primary crusher that did not require a primary feeder, scalper, and the associated infrastructure therein Minimizing the need for high cost stationary grids to control topsize underground was a requisite, and the large topsize acceptance was met with the UG pact primary crusher for above and underground Semimobile primary gyratory stations Innovative design SemiMobile Primary Gyratory crusher station designed to meet strict industrial safety standards and with extensive maintenance access Monorail for safe motor maintenance Dedicated area to safely monitor and service the crusher per recommendationsPrimary gyratory stations Automation PDF To be used during crusher maintenance when the pocket is clean and the spider has been removed With the primary corral in place, workers can be in the dump pocket without any annoying lifelines All of our other crusher rebuild tooling can be used while the primary corral is in placePrimary Corral – TriStar Design Manufacturing, Inc

Design Parameters Of Primary Crushers India

Primary Crusher Design Primary crusher detail design and main parameters underground primary crusher plant design is the difference between primary and secondary crushers difference between primary crusher and secondary crushers contact supplier primary crusher selection design how you select your primary crusher will be based on About products and suppliers: Purchase primary crusher from certified vendors only on Alibaba Metals are a part of everyday life, from utensils to jewelry to construction materialUnless the raw material is processed properly, there are high chances that the final products might lack in strength or durabilityBest Quality primary crusher AlibabaCrusher selection level primary crusher selection design ultimately the mining sequence will certainly impact the primary crusher selection where you will mine ore and where from is a deciding factor not so much for picking between a jaw or gyratory crusher but its mobility level primary crusher secondary crusher 210 mw coal power primaryreadPrimary Coal Crusher Design moribitoPrimary crushing of lumps The robust KVB series primary lump crushers are suited to the coarse grinding of agglomerates and lumps which are hard and brittle Should the product still be too coarse after the primary crusher, we recommend using our MKB lump crusher to grind the coarse goods to Primary lump crusher KVB Paul Groth Mühlenbau Impact Crusher Design And Calculations Crushing Plant Design and Layout Considerations Operating schedule calculation for 3 x 8 hours per shift rocks per year 365 (1) Wright Engineers Ltd Internal study of Primary Crusher Design, 1982 "Computer Aided Design of Jaw crusher" Scribd "Computer Aided Design of Jaw crusher"Internal Study Of Primary Crusher Design 1982

internal study of primary crusher design by boyd k l

Internal Study Of Primary Crusher Design By Boyd,K L grinding roller crusher 28bm series29 internal study of primary crusher design by boyd k l dowall bl crusher supplier in indonesia latest artificial sand raymond coal crusher feldspar inpit crusher and conveuor technology vsi crusher bauxite group stone crusher Get priceMcLanahan offers a wide selection of Impact Crushers for quarried limestone and semiabrasive minerals McLanahan draws from the 75 years of field experience with the Universal line of Impactors, which includes impact breakers and Andreasstyle impactors At present, we offer the New Hollandstyle primary impact breaker and the MaxCap XSeries Primary, providing a means to reduce quarry shot Impact Crushers Primary McLanahan Below the surface: Setting up an underground primary jaw crusher pcmadmin 04/01/2014, 2:42 pm 19/03/2020 438 Real estate in an underground mine is not cheap, so the design of primary crushing plants has more limitations underground than on the surfaceBelow the surface: Setting up an underground primary From large primary jaws and gyratories to cone and impact crushers for tertiary and quaternary finishing, Outotec equipment is manufactured to meet your material reduction requirements The crushers are built to perform with the lowest cost per ton, featuring a unique combination of crusher cavity design, crushing forces, reliability and Crushing Outotec PRIMARY CRUSHER SELECTION CRITERIA • Will it produce the desired product size at required capacity • Will it accept the largest feed size expected • What is the capacity to handle peak loads • Will it choke or plug • Is the crusher suited to the type of crushing plant design • Is the crusher suited for underground or inpit duty Mineral Processing Crushing Plant design,