vertical milling machine working principal

2020-01-08T05:01:38+00:00

vertical milling machine working principal

vertical milling machine working principal Course Descriptions Machining These skills are necessary for students interested in working with manual milling machines and working in maintenance shops or job shops MACH 1073 Operations III 90 Hours Students in this course will continue instruction in the setup, operation, and programming Introduction: Milling is the cutting operation that removes metal by feeding the work against a rotating, cutter having single or multiple cutting edges Flat or curved surfaces of many shapes can be machined by milling with good finish and accuracy A milling machine Principle and Working of MILLING MACHINE Working of Vertical Milling Machine: In this milling machine workpiece is fixed without any movement, this used to feed against the cutting tool metal removed from the workpiece is done in the form of chips, we can move the head in up and down direction or any angles by this, we can perform many operations like grooves, slotsVertical milling machine: Working, Main Parts, Adjustable working table of milling machine will hold the workpiece and movement of adjustable working table will govern the feeding of workpiece against rotating milling WORKING PRINCIPLE AND TYPES OF MILLING The working of a milling machine has some phases of cutting These milling processes involve the following phase of cutting: Milling cutters Having a lot of cutting tools use for the working of milling process these cutters named end mills are designed with a special cutting surfaces on their end surfaces so they can perform drillingThe working principle of milling machine

The Working Principle of the Milling Machine

The vertical milling machine and the horizontal milling machine are two categories of the milling machine In vertical milling, the spindle axis is in a vertical position It requires a smaller work area, while the horizontal milling aligns the axis horizontally and needs a more prominent work site Vertical milling In this chapter, the working principal of milling machine is presented The categorization of milling cutter with its parts and angles are presented Machining parameters which affect the surface roughness, chip thickness formation and factors influence surface roughness in milling machine are also presented in The Working Principle of Milling MachinesWorking Principle of Milling Machine Milling is a metal removal process by means of using a rotating cutter having one or more cutting teeth as illustrated in figure Cutting action Milling Machine Types, Working, parts, Operations Spindle is the main part of the machine which hold tool at right place in vertical milling machine and hold arbor in horizontal milling machine It is a moving Milling Machine: Parts and Working mech4study1 天前 Milling Machine Definition: The milling machine is a type of machine which removes the material from the workpiece by feeding the work past a rotating multipoint cutterThe metal removal rate is higher very high as the cutter has a high speed and many cutting edges It is the most important machine in the tool room as nearly all the operations can be performed on it with high accuracyMilling Machine: Definition, Parts, Operation, Working

vertical milling machine working principal

vertical milling machine working principal Course Descriptions Machining These skills are necessary for students interested in working with manual milling machines and working in maintenance shops or job shops MACH 1073 Operations III 90 Hours Students in this course will continue instruction in the setup, operation, and programming In this chapter, the working principal of milling machine is presented The categorization of milling cutter with its parts and angles are presented Machining parameters which affect the surface roughness, chip thickness formation and factors influence surface roughness in milling machine are also presented in The Working Principle of Milling Machines 4 Vertical Milling Machine Your Vertical Milling machine is a Column and knee type Milling Machine minus the overarm arrangement and has a vertical spindle head at the top of the column The milling head of your Vertical Milling Machine may be the fixed head, sliding head or swiveling head, or a combination of swiveling and sliding headDifferent Types of Milling Machines and How They Work 13 WORKING PRINCIPLE OF MILLING MACHINE Working of a milling machine is based on the fact that milling cutter is fed against workpiece This is achieved by developing relative motion with precise control between workpiece and rotating milling cutter Feed motion is generally given to the workpiece through its holding deviceUNIT 1 MILLING Milling IGNOU machines use a 3D Cartesian coordinate system Figure 10 shows a typical Vertical Milling Center (VMC) Parts to be machined is fastened to the machine table This table moves in the XYPlane As the operator faces the machine, the XAxis moves the table leftright The Y Unit 3: Vertical Milling Center Machine Motion

principal parts of milling machine cestirisnl

Milling Machine Parts and their Function HubPages Dec 24, 2009 The principle parts of milling machine are given: Base; The base of the machine is Grey iron casting accurately machined on its top and bottom surface and serves as a foundation member for all the other parts which rest upon it The milling machine which has a knee like projection at the middle is called kneetype milling machine It is characterised by a vertical adjustable work table resting on a saddle supported by a knee 4 RamType Milling Machine A milling machine which has a ram on the top of the column is called ram type milling machineWhat is Milling Machine Operation, Parts and Types Milling is the machining process in which the removal of metal takes place due to the cutting action of a rotating milling cutterIn a milling machine, the cutter is rotating due to workpiece is fed against itThis machine can hold more than one tool at a time The cutter rotates at high speed, and because of the many cutting edges, it removes metal at a very fast rateMilling Machine: Parts, Types, Operations, Milling Milling cum drilling machine is broadly adopted in the industries where there is a requirement of mixing and grinding of solid and liquid substances Pillar drill machine (also referred as drill press) is used in commercial applications where there is a requirement of bulk production of drilled materials in various size and shape like metal Drilling Machine Working Principle Applications Introduction: The shaper is a machine tool used primarily for: 1 Producing a flat or plane surface which may be in a horizontal, a vertical or an angular plane 2 Making slots, grooves and keyways 3 Producing contour of concave/convex or a combination of these Working Principle: The job is rigidly fixed on the machine table The single Principle and Working of SHAPER MACHINE

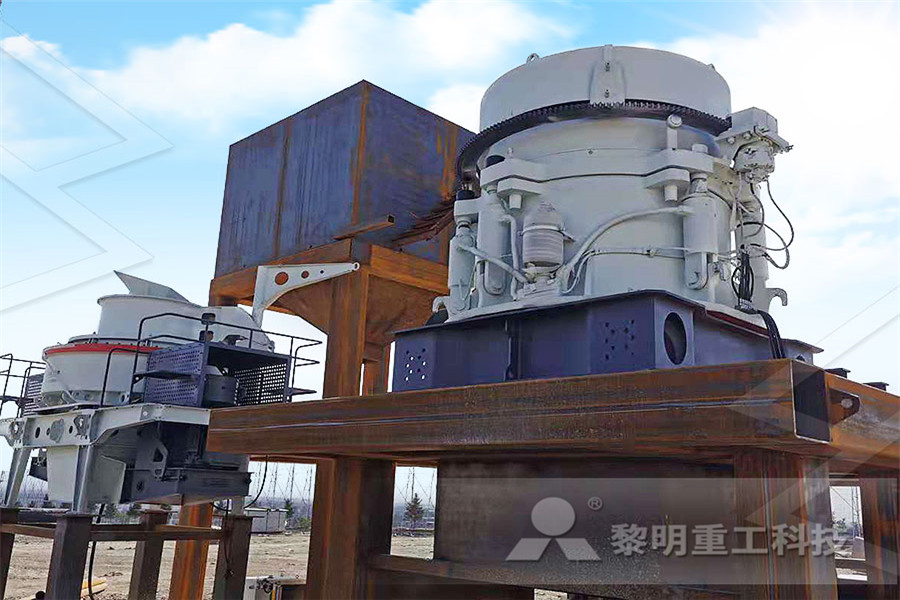

VERTICAL KNEE COLUMN MILLING MACHINE (LARGE)

VERTICAL KNEE COLUMN MILLING MACHINE (LARGE) Sl No Nomenclature Specification A/U Qty (a) (b) (c) (d) Vertical Knee Column Milling Machine (Large) with all standard and additional accessories as per specification below: Nos 05 1 Specification: a Working working principle of vertical milling machine milling machine working principle vertical milling machine working principal The working principle of vertical milling machine Labor Forprinciple and working of milling machine The milling machine which has a knee like projection at the middle is called kneetype milling machine It is characterised by a vertical adjustable work table resting on a saddle supported by a knee 4 RamType Milling Machine A milling machine which has a ram on the top of the column is called ram type milling machineWhat is Milling Machine Operation, Parts and Types vertical roller mill separator working principal in indonesia Vertical roller mill in the mining industry has been in an important position, because of its simple operation, low cost, income and other characteristics, by the praise vertical mill buyers, in order to better understand the vertical mill, this article details introduction Operation and working principle of the roller millvertical roller mill separator working principal in 3axis Vertical Machining Center Home > Machining Center > 3axis Vertical Machining Center VM12100B Vertical Machining Center The VM12100B spindle is a true cartridge type unit supported by high precision ceramic ball bearings that offers minimized noise, vibration and thermal growthVM12100B Vertical Machining Center

Vertical Machining Centers (VMCs) Modern Machine

Ganesh T500 vertical machining centers offer fast machining capabilities in a very compact machine Solid Construction and Fourth Axis Are Highlights of Shop’s Newest VMC A vertical machining center with a fourth axis from Kent USA enables Mega Industries LLC to China Vertical Boring Machines manufacturers Select 2021 high quality Vertical Boring Machines products in best price from certified Chinese Boring Machine, Other Machines suppliers, wholesalers and factory on MadeinChinaChina Vertical Boring Machines, Vertical Boring MILLING MACHINE Milling machine is a machine which is used to perform various operations like cutting and shaping of solid materials Milling is most common process nowadays used in industries and in workshops for machining of different materials to precise sizes and shapes A milling machine can be a Horizontal or Vertical which depends over Advantages And Disadvantages Of Milling Machine Milling Machine Parts and their Function HubPages Dec 24, 2009 The principle parts of milling machine are given: Base; The base of the machine is Grey iron casting accurately machined on its top and bottom surface and serves as a foundation member for all the other parts which rest upon itprincipal parts of milling machine cestirisnlWorking And Construction Of Vertical Raw Mill FOB Reference Price:Get Latest Price Working Of Vertical Raw Mill We are a largescale manufacturer specialiing in producing various mining machines including different types of sand and gravel equipment milling equipment mineral processing equipment and building materials equipmentWorking And Construction Of Vertical Raw Mill